CNC Milling

At a Glance

Lifecycle

Lead Time

Materials

Tolerance

About the Process

If your part is any sort of shape other than cylindrical, or lacks rotational symmetry about some imaginary axis through the part body, then a CNC mill is likely the machine for you. With milling, the stock that the part will be cut from is usually a six-sided bar or sheet of material (though it can also be a cylindrical rod). This stock is fixtured to the bed of the machine and the features of the part are cut using a rotating tool such as a drill or endmill.

With a 3-axis machine, the rotating tool mentioned above can translate relative to the part in the X, Y, and Z axes (thus the name), but is fixed in a vertical (or horizontal, depending on the machine) orientation. With modern CNC mills, the tool can also move in any combination of the 3 axes simultaneously.

A 5-axis machine is capable of the same movements as a 3-axis machine, but with added rotation about the X and Y axes. It is usually the bed that rotates rather than the toolhead, though both types of machines do exist. This added rotation allows for much more freedom when machining each setup.

Materials

Plastics

ABS

A low-cost engineering plastic widely used for

pre-injection molding prototypes. CNC machined

ABS is a great option for production-like parts

where detail and mechanical properties are important.

Polycarbonate

PC is one of the most common plastics used in

manufacturing. Famous examples of the material

are first generation MacBook laptops, safety goggles,

and optical disks.

Polycarbonate is heat-resistant, impact-resistant, flame-

retardant, and one of the most recycled plastics in the world.

PMMA (Acrylic)

Acrylic is a scratch-resistant plastic, available optically

clear or opaque. It is often used for tanks, panels,

and optical applications. It can be somewhat brittle in

thin walled areas, so it is not recommended for delicate or

complex geometries.

This plastic is also known as PMMA, an abbreviation

of its full chemical name, polymethyl methacrylate

as well as by the trade names Plexiglas and Lucite.

Nylon

Nylon 6/6 is the most commonly used of the Nylon

family of plastics. It enjoys relatively high chemical

and heat resistance, and is stiff enough to retain

its shape, but tough enough not to permanently

deform under load.

Two of the most notable use cases for Nylon

are in medical devices and electronics insulation,

notably screws and spacers for panel mounted

circuit boards.

Nylon GF

Glass reinforced Nylon material for performance parts

requiring high stiffness and low abrasive wear.

PEEK

A high-performance engineering plastic with outstanding

resistance to harsh chemicals, and excellent mechanical

strength and dimensional stability. Suitable for

continuous use at temperatures up to 170C

Ultem

A material which is extremely strong and stiff with

high dielectric strength. Resistant to hydrolysis

when exposed to hot water and steam

Delrin

Delrin (generic: acetal) is a low-friction, high-stiffness

material. It is used in applications ranging from auto

parts to musical instruments. With a relatively high

toughness and minimal elongation, Delrin boasts excellent

dimensional accuracy.

HDPE

HDPE is a naturally opaque white because of its

crystalline structure, but is also available dyed

black in more limited stock sizes. It has a

waxy finish leveraged for low-friction applications.

It is also an excellent electrical insulator as well as being

moisture and chemically-resistant.

PP

Polypropylene (PP) resists most solvents and chemicals,

which makes it a wonderful material to manufacture

laboratory equipment and containers for a variety of

applications. PP also offers good fatigue strength.

Materials

Metals

Aluminium

Aluminum is one of the most commonly used metals in

the world because of its excellent strength-to-weight

ratio, low cost, and recyclability. Shapefy offers

Our standard alloy on platform is 6061, a versatile

and easy-to-machine metal. It is corrosion-resistant,

non-magnetic, and heat treatable.

7075 Aluminum is a hard, high strength alternative

to 6061 Aluminum. It is often used for parts in

high-stress applications, and is also corrosion-resistant,

non-magnetic and heat treatable.

Also known as jig plate or cast tool, MIC6 is a cast

aluminum alloy that is great for tight tolerance

applications due to it being stress-relieved. It is most

commonly used in precision machine tables and tooling.

MIC6 is non-magnetic and not heat treatable.

Brass

360 Brass is also known as free machining brass,

due to it having the highest amount of lead content of

any brass alloy. This excellent machinability comes with

minimal tool wear. It is commonly used for a variety

of parts such as gears, lock components, pipe

fittings, and ornamental applications.

Copper

Copper has a shiny reddish-orange finish, which

varies slightly based on the surface finish method.

Offers excellent thermal and electrical conductivity.

Available in 110 and 101 Alloys.

Stainless Steel

Stainless steel is highly resistant to corrosion and rust,

making it suitable for situations where a part

may be exposed to the elements for long period of time.

Stainless steel is also fairly malleable and ductile.

Good for industrial applications, fittings, fasteners,

cookware, medical devices.

making it suitable for situations where a part

may be exposed to the elements for long period of time.

Stainless steel is also fairly malleable and ductile.

Good for industrial applications, fittings, fasteners,

cookware, medical devices.

Steel

1018 Steel is a mild, low carbon steel that is machinable,

weldable and useful where high-strength is not

required, such as fixtures and mounting plates. It is

magnetic and heat treatable.

4140 alloy steel is generally harder and stronger than

carbon steel. Additionally, it provides high impact

resistance, fatigue strength, and torsional strength

which makes 4140 a great choice for drive shafts,

axles, and torsion bars. In terms of hardening,

4140 can be hardened using a variety of methods

such as cold working, or heating and quenching.

weldable and useful where high-strength is not

required, such as fixtures and mounting plates. It is

magnetic and heat treatable.

4140 alloy steel is generally harder and stronger than

carbon steel. Additionally, it provides high impact

resistance, fatigue strength, and torsional strength

which makes 4140 a great choice for drive shafts,

axles, and torsion bars. In terms of hardening,

4140 can be hardened using a variety of methods

such as cold working, or heating and quenching.

Titanium

Titanium’s properties, which are a combination of high

strength, stiffness, toughness, low density, and good

corrosion resistance provided by various titanium

alloys at very low to elevated temperatures, allow

weight savings in aerospace structures and other

high-performance applications.

Titanium is a low-density element (approximately 60%

of the density of iron) that can be strengthened by

alloying and deformation processing. Titanium is

nonmagnetic and has good heat-transfer properties.

Surface Finishes

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.This way aesthetic needs or technical requirements can be achieved.

Name

Description

Design Recommendations

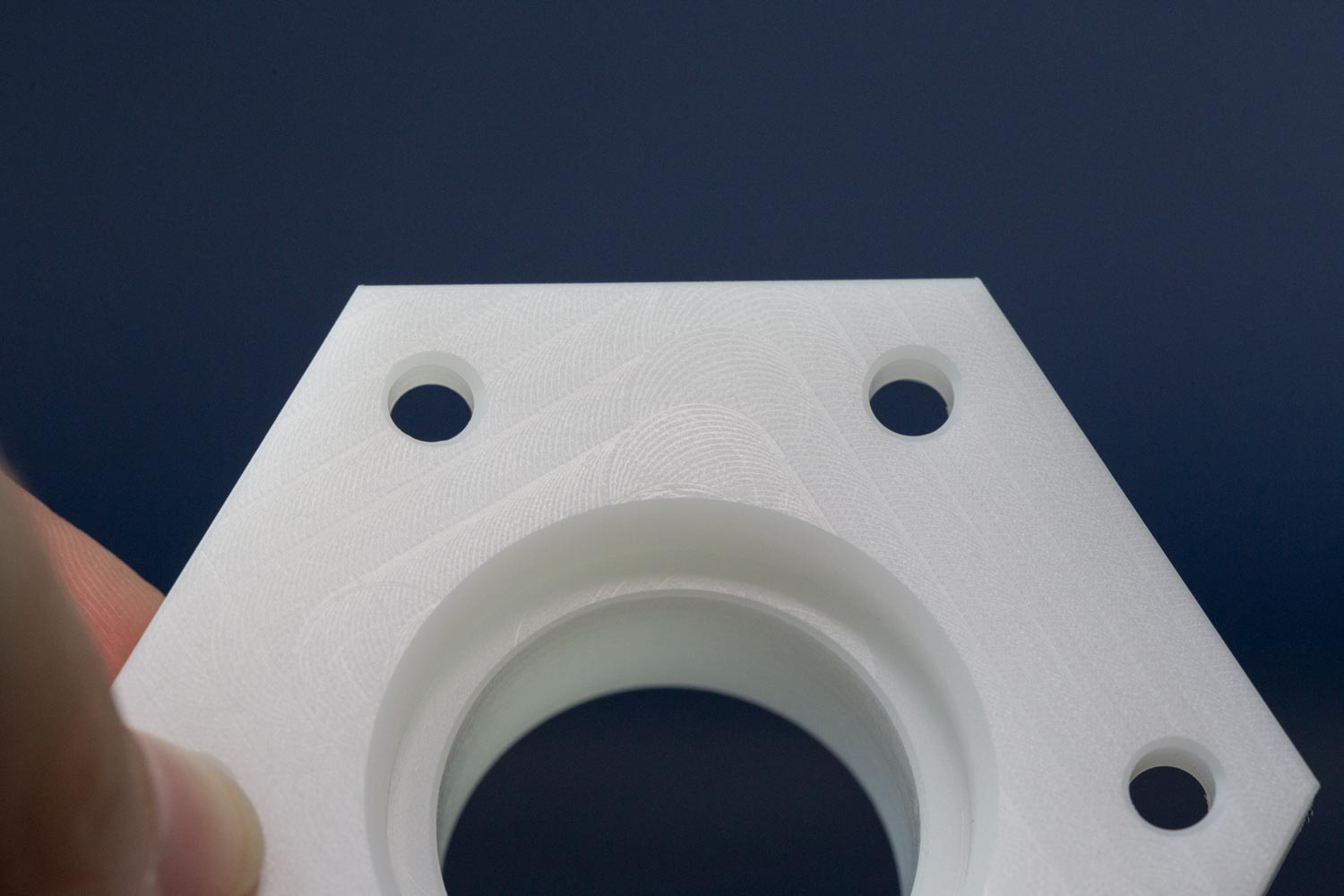

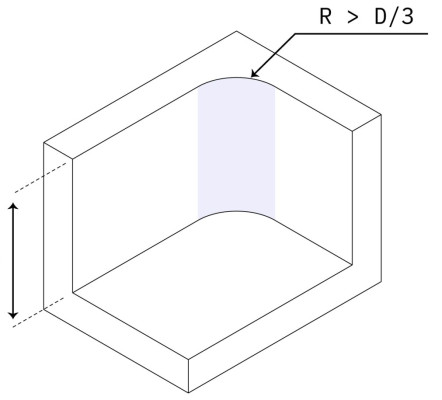

Internal Radius

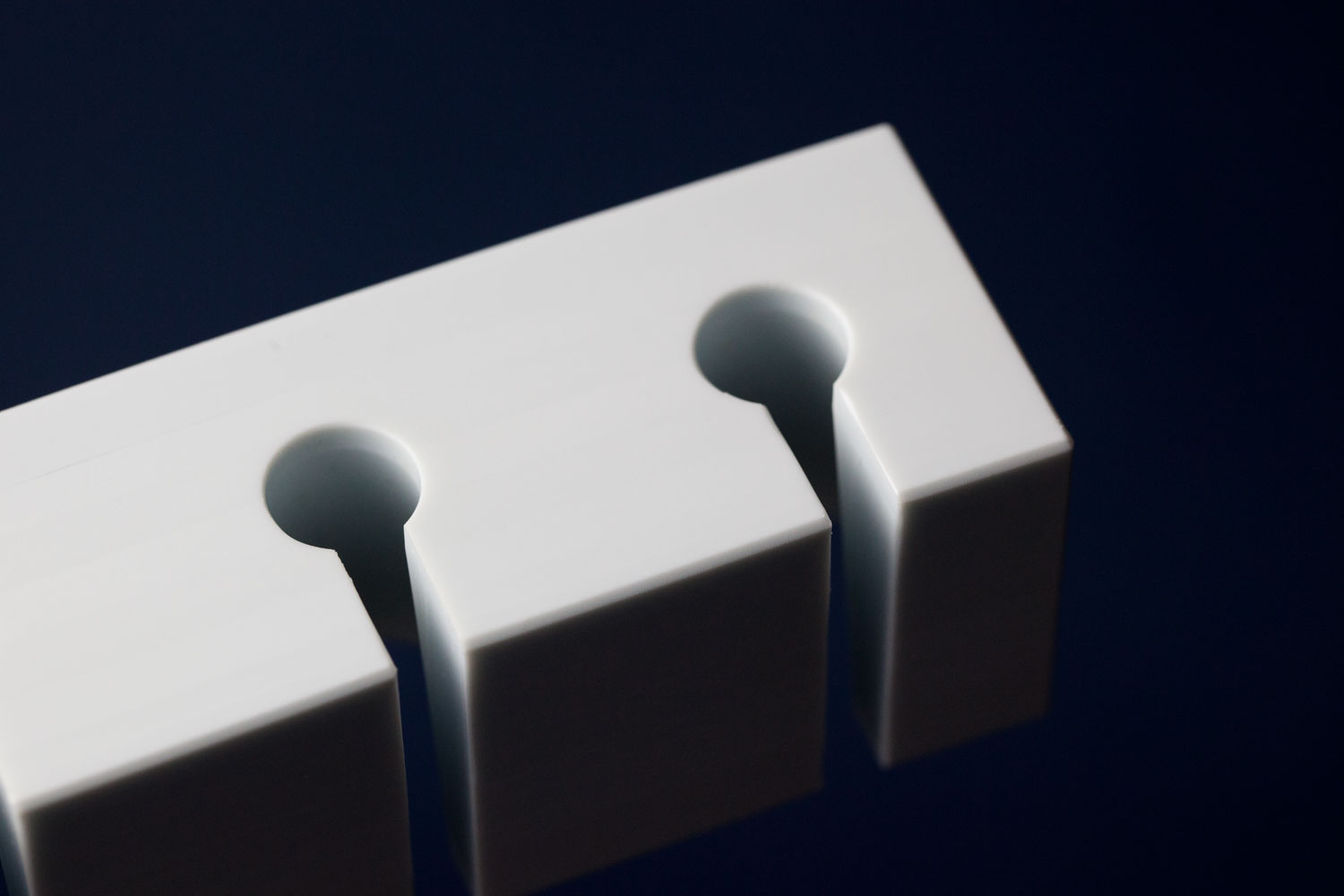

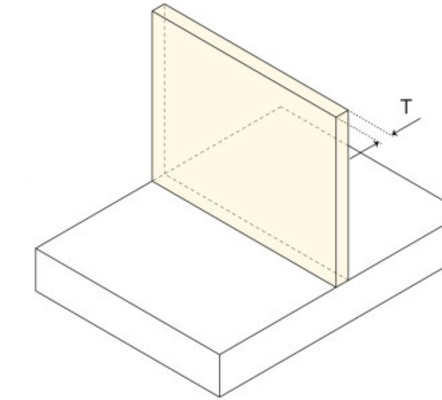

Wall thickness

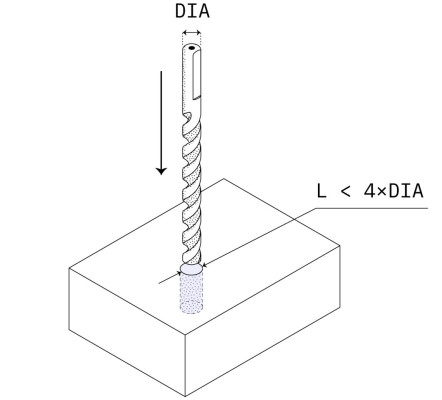

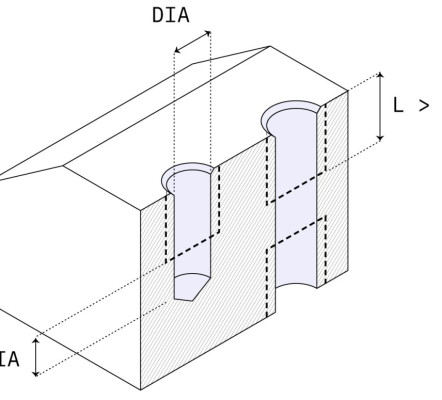

Holes

Threads

R 0.25mm

Recommended:

R 8

0.5 mm (for metals)

1.0 mm (for plastics)

Recommended:

0.8 mm (for metals)

1.5 mm (for plastics)

Diameter: Ø 0.5

Depth: 10 x diameter

Recommended:

Diameter:standard drill bit sizes

Depth: 4 x diameter

Recommended: M6 or larger