CNC Milling

We offer both 3 and 5-axis machining capabilities. To optimize for speed of production, we recommend minimizing the number of setups to leverage 3-axis machining.

To learn more about our CNC milling capabilities, visit our Capabilities Guide.

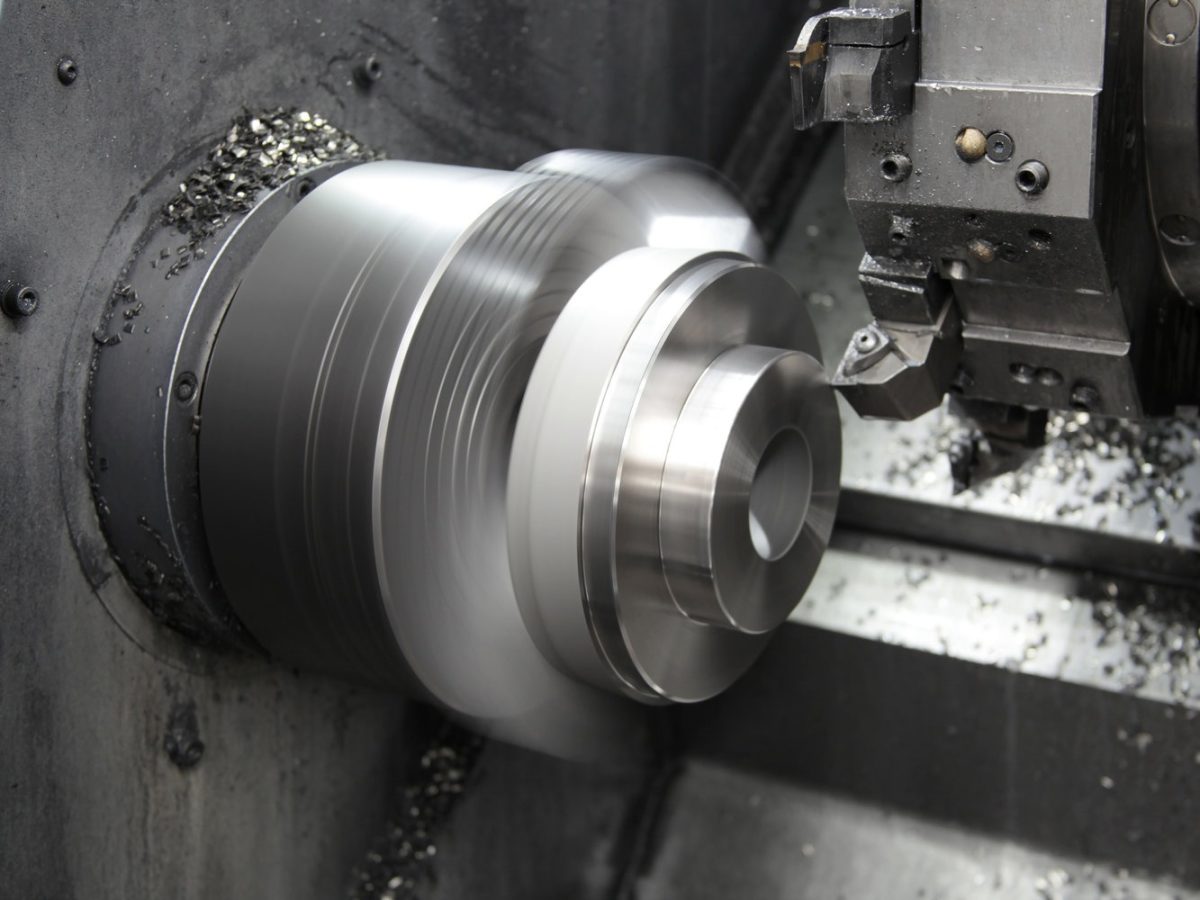

CNC Turning

We offer both standard and live-tooling CNC turning. As with CNC milling, we recommend limiting the need of live-tooling to speed up the prototyping process.

To learn more about our CNC milling capabilities, visit our Capabilities Guide.