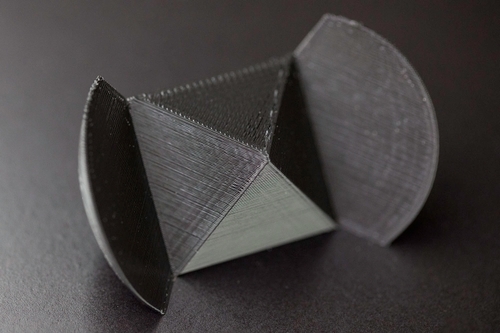

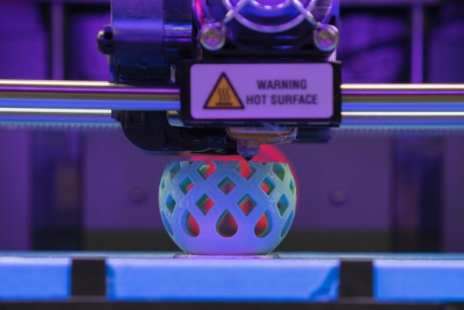

FDM

FDM is the most widely available 3D printing process, mainly used for low-cost prototyping and design verification with very fast turn around times.

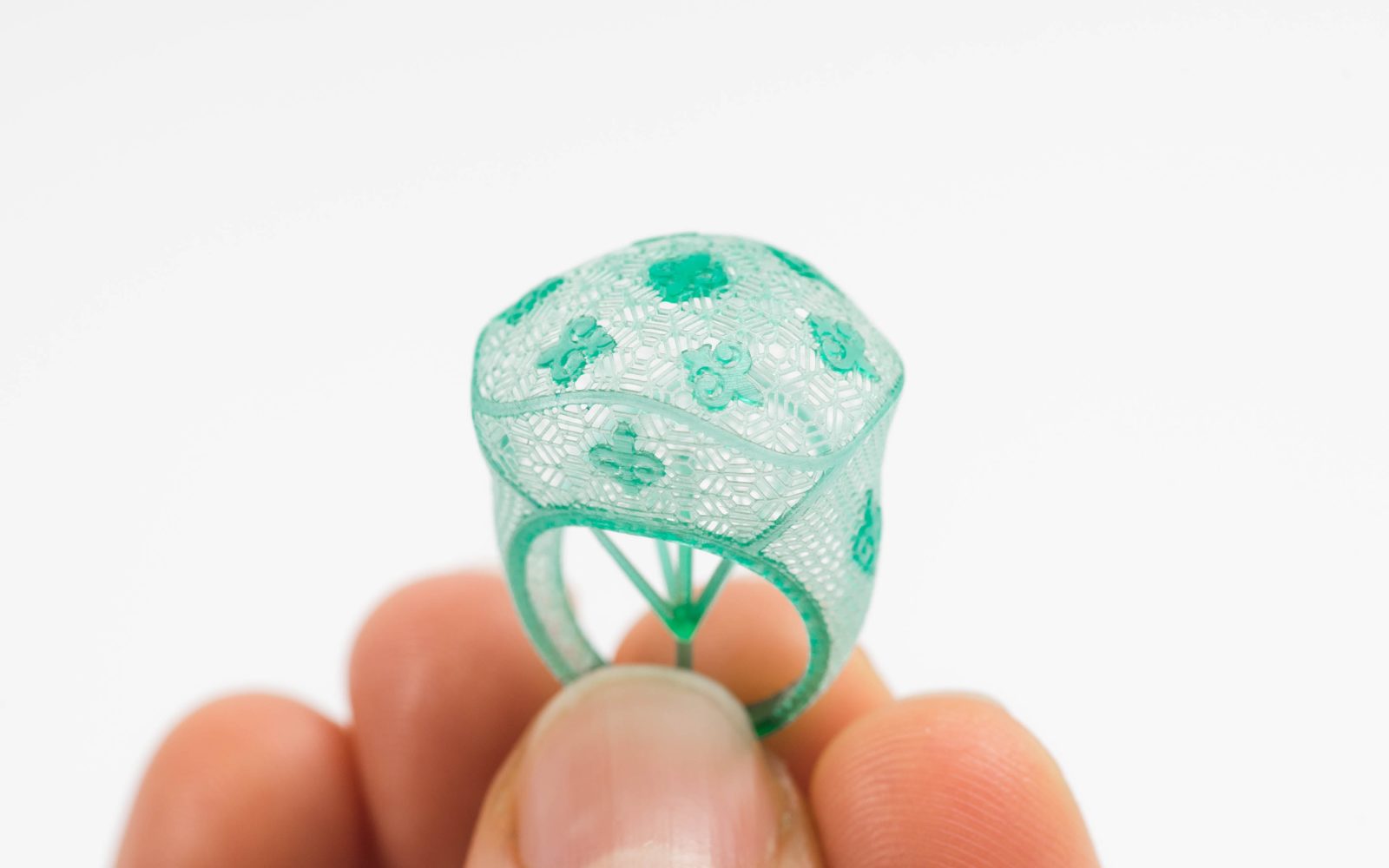

SLA

SLA is most suitable for visual applications where an injection mold-like, smooth surface finish, and a high level of feature detail are required.

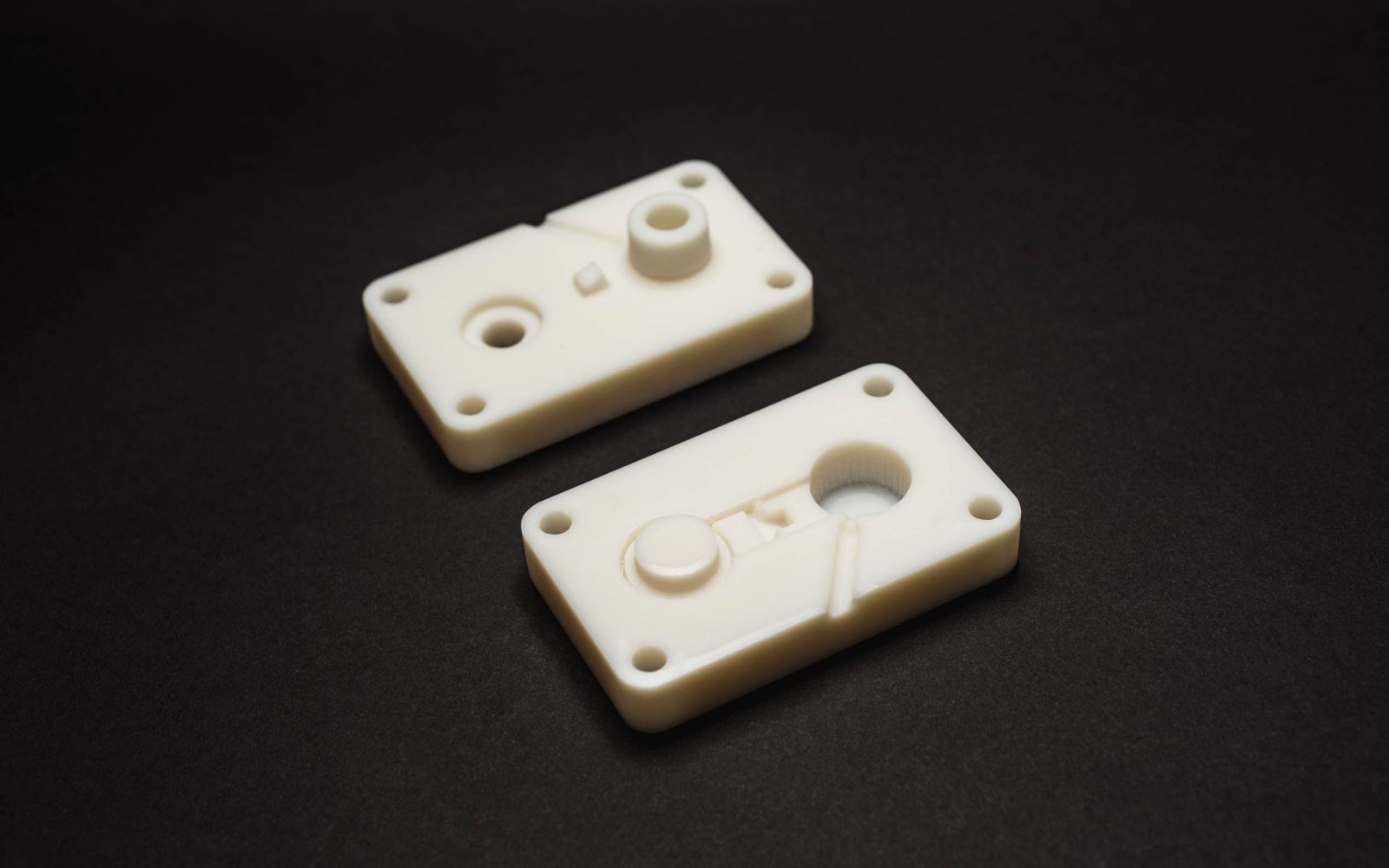

SLS

SLS is used for both prototyping and small-batch production of functional plastic parts with good mechanical properties.

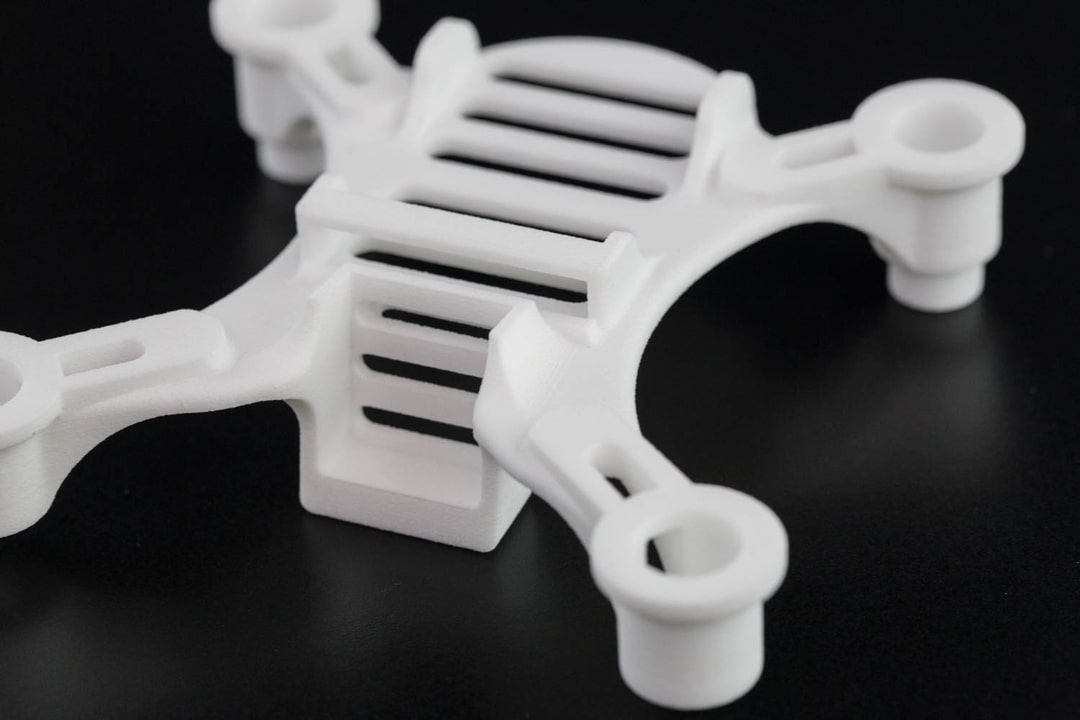

MJF

HP's Multi Jet Fusion (MJF) can be used for both prototyping and small-batch-production of functional plastic parts.

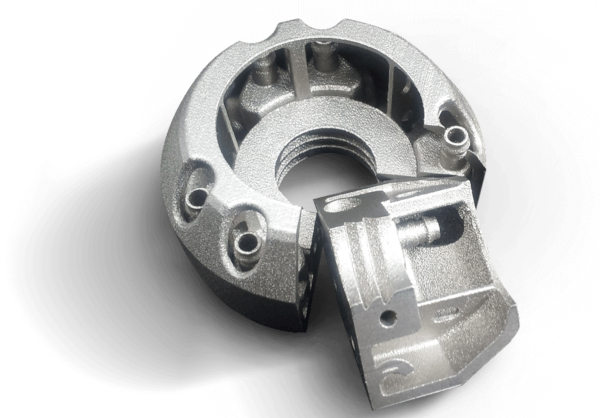

DMLS

DMLS/SLM produce high performance, end-use metal 3D printed parts for industrial applications in aerospace, automotive and medical.