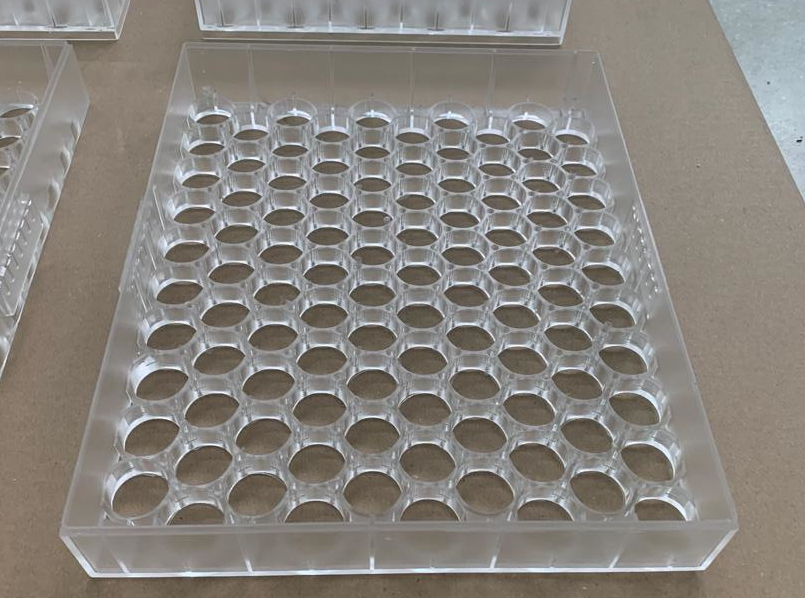

Production Quality at Low Volumes

This process is a quick, cost-effective way to produce 10-200 units with production-level quality. Typically, each silicone mold will produce upto 20 castings.

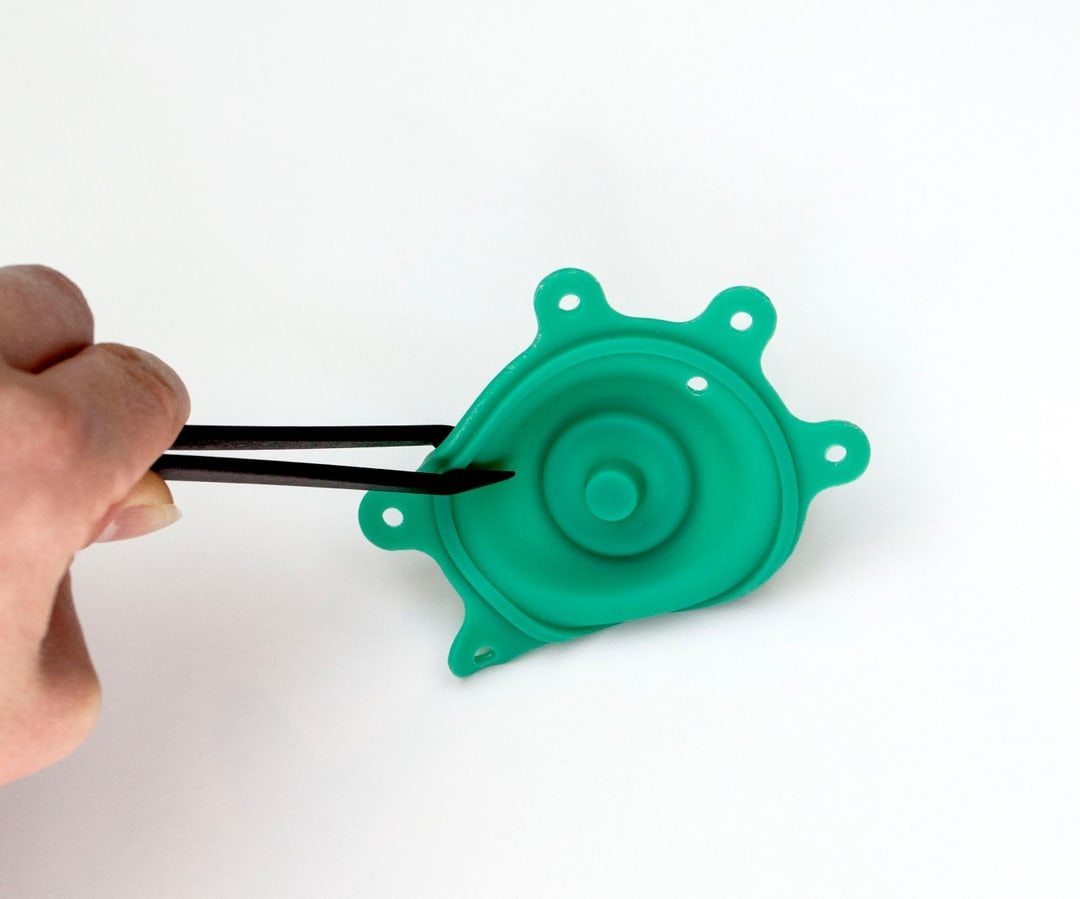

Complex Elastomeric Parts

Silicone moulding is ideal for prototyping elastomeric parts such as complex gaskets and overmolds on rigid parts.

High Level of Detail

Silicone moulding allows for almost limitless complexity, including sharp internal corners unachievable with CNC machining, and designs without draft or uniform wall-thickness that can’t be injection molded.