About the Process

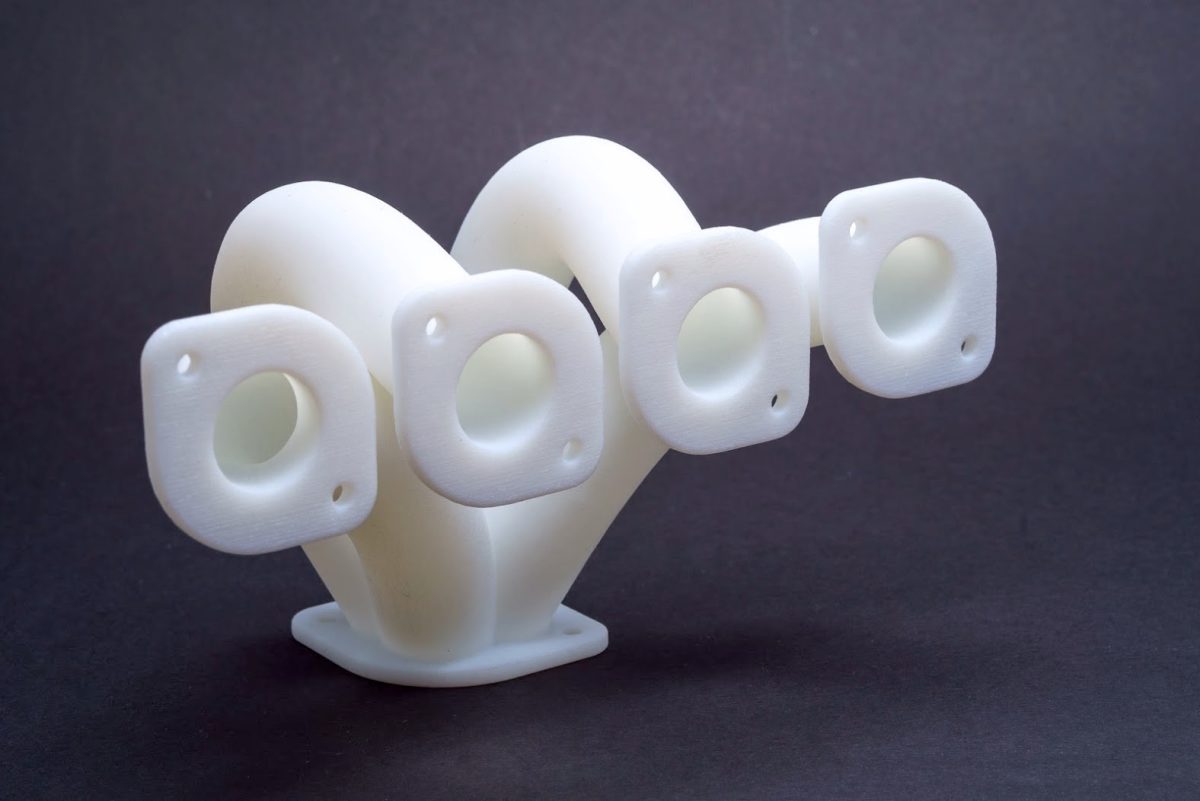

Selective Laser Sintering uses high-powered lasers to sinter powdered material, binding it together to create a solid structure. It is often confused with another similar process called Selective Laser Melting (SLM), the difference being that it only sinters the powders together as opposed to achieving a full melt.

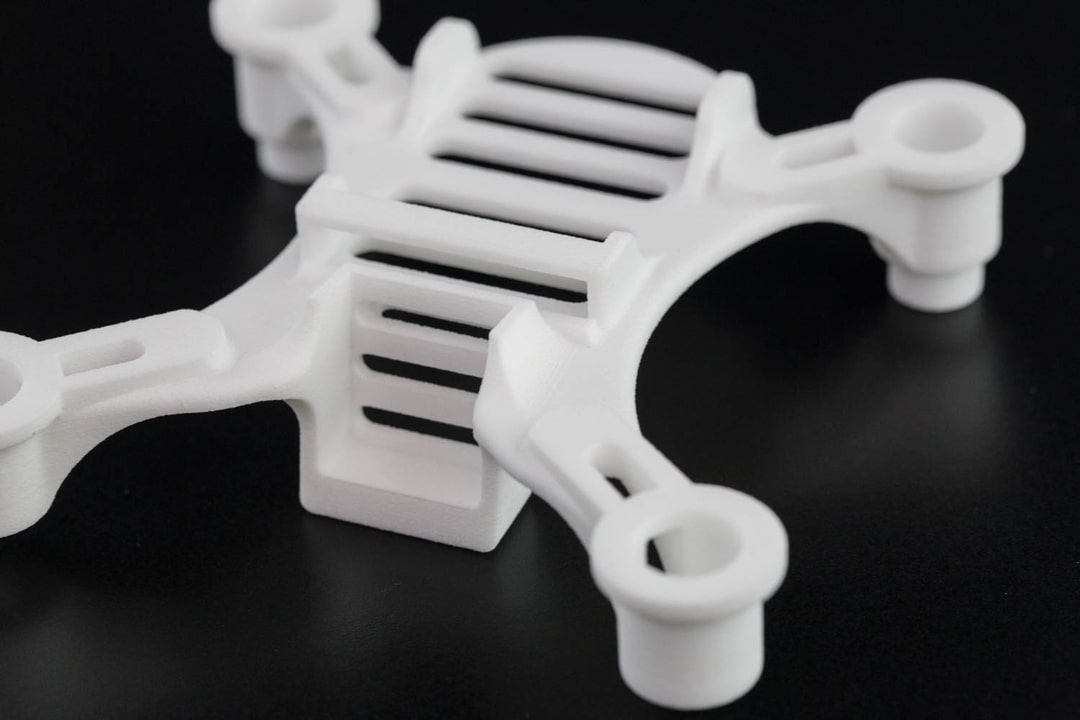

Parts are supported by unsintered powder in each layer, which remain spread across the build volume until each layer is fused together. Once complete, the part is removed from the remaining powder and cleaned by hand and using water/air jets.

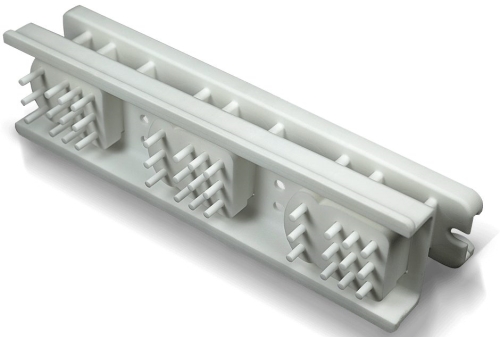

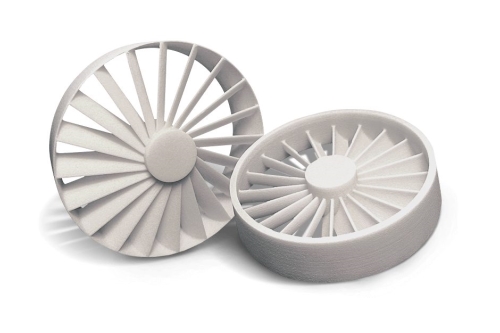

While parts created using this technology can contain some metal, they are usually plastic composites that present a good strength to weight ratio and can be acquired relatively cheaply. For parts that must be structurally as sound as forged solid metal, DMLS is required. Still, the high level of accuracy, relatively cheap feedstock, and high temperatures achievable with SLS printing make it an incredibly useful technology with a broad range of applications ranging from architectural models to control surfaces of aircraft and surgical tools.