Direct Metal Laser Sintering (DMLS)

At a Glance

Lifecycle

Lead Time

Materials

Resolution

About the Process

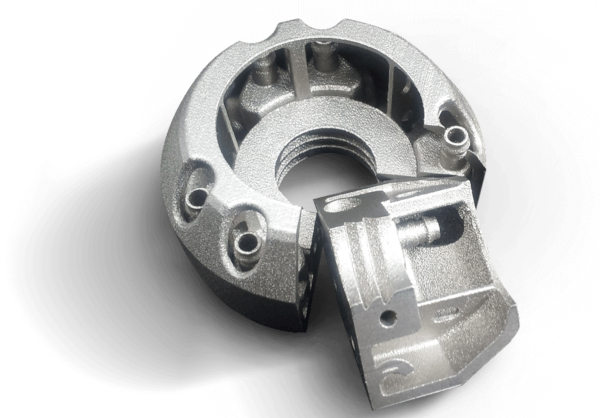

Direct Metal Laser Sintering (DMLS) is a direct metal laser melting (DMLM) or laser powder bed fusion (LPBF) technology that accurately forms complex geometries not possible with other metal manufacturing methods.

DMLS parts are stronger and denser than investment casted metal parts, and they can help you get to market first with faster turnaround times.Metal 3D printing is an ideal process for complex oil and gas components, custom medical guides, part-consolidated aerospace parts and tough functional prototypes.

DMLS materials build fully dense, corrosive resistant and highly robust metal parts that can be further treated through heat, coating and sterilization. Utilize the design freedom of DMLS and produce accurate metal components in less time than other manufacturing methods.

Materials

Stainless Steel Cx

A tooling grade steel characterized having a good corrosion

resistance combined with high strength and hardness.

Great for Injection moulding tools and other industrial

applications.

Material

Lead Time

Resolution

Pricing

Max Temp

NickelAlloy IN718

Heat and corrosion resistant nickel alloy. Characterized

by having good tensile, fatigue, creep and rupture strength

at temperatures up to 650 °C. Ideal for many high

temperature applications such as gas turbine parts,

instrumentation parts, power industry parts etc.

Material

Lead Time

Resolution

Pricing

Max Temp

Aluminium

A light metal good for functional prototypes,

series-production parts, Aerospace and automotive

etc. Ideal for applications that require a combination

of good thermal properties and low weight.

Material

Lead Time

Resolution

Pricing

Max Temp

Maraging Steel

Maraging steel offers an unusual combination of high

tensile strength and high fracture toughness.

Ideal for applications which require high

strength-to-weight material

Material

Lead Time

Resolution

Pricing

Max Temp

Stainless Steel 316L

Characterized by having a good corrosion resistance

ideal for Lifestyle/Consumer, Automotive/Industrial,

Aerospace and Turbine industries.

Material

Lead Time

Resolution

Pricing

Max Temp

289 °C @ 0.45 MPa

Titanium

A light alloy characterized by having excellent

mechanical properties and corrosion resistance

combined with low specific weight and biocompatibility.

Ideal for many high-performance engineering applications.

Material

Lead Time

Resolution

Pricing

Max Temp

Design Recommendations

Max Part Size

Min Feature Size

Tolerance

Min Wall Thickness

Min Hole Diameter

Min Gaps for Mating Parts

+ Design for Manufacturing Tips

- Overhangs with an angle greater than 35 degrees can be built without support structures.

- Superfluous volumes should be avoided when using this technology

- Overall, the most ideal geometries are small, self-supporting parts that would be difficult to manufacture through machining