About the Process

Multi Jet Fusion is a new 3D printing technology, offering you more possibilities for complex, lower-cost parts. Whether used in serial production for single parts or batch manufacturing by shipsets of multiple part numbers, Multi Jet Fusion offers a faster, more cost-effective process for 3D printed parts.

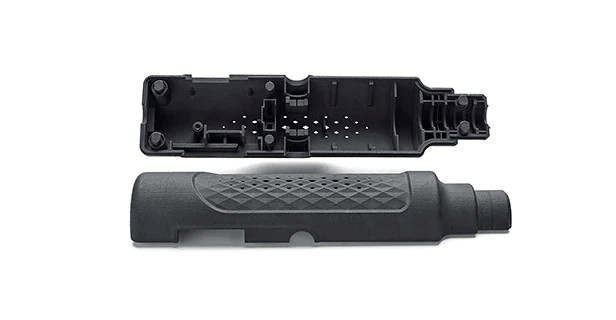

Multi Jet Fusion is ideal for hidden applications like complex thin-wall ductwork, connectors, non-cosmetic housings, brackets, covers, wiring clips, guides and grommets.

In MJF, parts are built by jetting a binding agent onto thin layers of polymer powder particles (typically nylon) and then sintering them using an IR heat source. With a layer height of 80 microns, parts have high density and low porosity, compared to PA 12 parts produced with Laser Sintering.

It also leads to an exceptionally smooth surface straight out of the printer, and functional parts need minimal post-production finishing. That means short lead times, ideal for functional prototypes and small series of end-parts.