About the Process

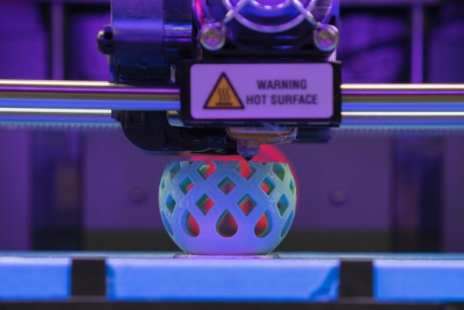

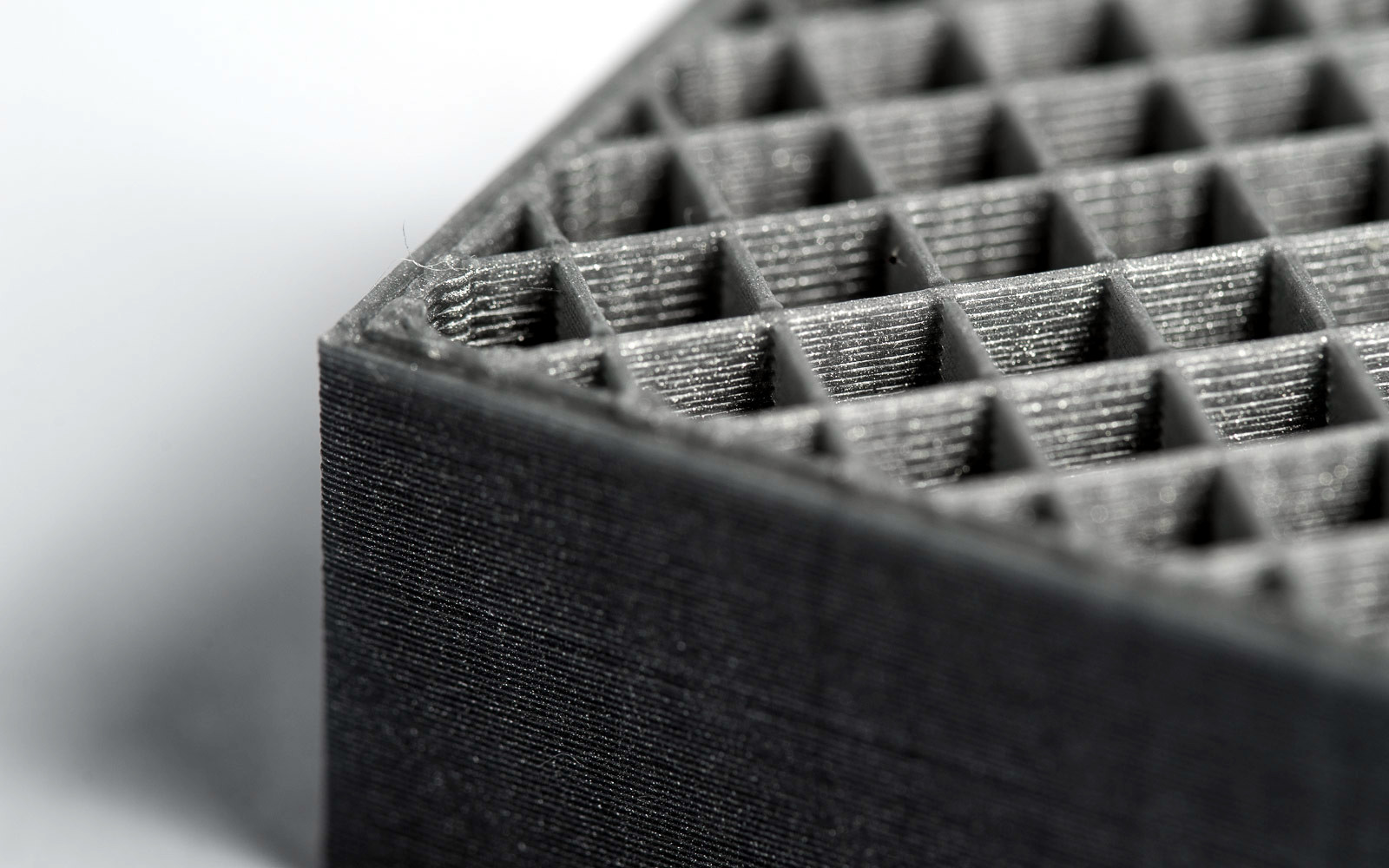

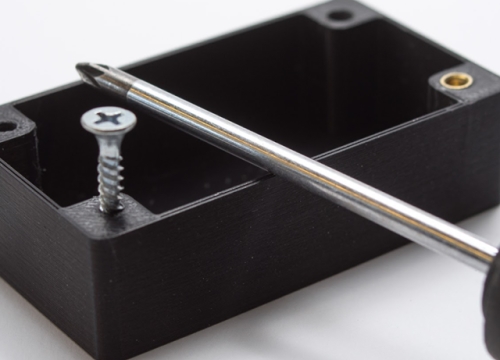

Fused deposition modeling (FDM) is a 3D printing technology (also known as additive manufacturing) commonly used for modeling, prototyping, and production applications. Each layer is created by extruding material from a nozzle to produce 3D objects. At Shapefy, all FDM prints are produced according to the resolution chosen by the customer keeping a balance of accuracy and strength with speed.

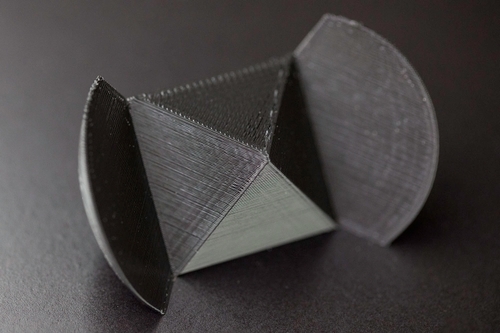

FDM processes require support material, either breakaway or soluble, so it’s important to keep this in mind when choosing this process as it can affect the final part.